Contact with

us for any

soluton

Call Anytime

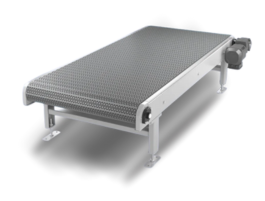

Modular Conveyors

Flexible, Customizable & Efficient Material Handling

A Modular Conveyor is a highly adaptable conveying system designed for industries that require flexibility, continuous operation, and easy maintenance. Unlike fixed conveyor systems, modular conveyors are built using interlocking plastic belt segments that can be configured into straight sections, curves, inclines, declines, and multiple layouts as per workflow requirements.

Packveyor’s modular conveyors are engineered for durability, smooth movement, and effortless cleaning, making them ideal for food processing, packaging lines, FMCG, assembly operations, and high-throughput manufacturing environments. Their modular structure allows quick modifications, making them one of the most versatile options for modern industrial automation.

Modular Conveyors:

Build Quality

Packveyor Modular Conveyors are built using premium-grade materials to ensure strength and long service life. The modular belt segments are made from high-density, wear-resistant polymers that offer excellent grip and stability. These belts run on corrosion-resistant SS or MS powder-coated frames that remain rigid even under continuous load. The belts glide smoothly over low-friction wear strips, reducing resistance and minimizing power consumption. The conveyor is driven by compact, energy-efficient motors that provide consistent torque while keeping noise levels low. Each component—belt links, sprockets, shafts, bearings, and guides—is designed for quick replacement, easy cleaning, and long-term functionality, even in demanding industrial environments.

Industrial Applications

Modular conveyors are widely used across industries where hygiene, flexibility, and automated handling are essential. In food and beverage processing, they support the movement of packaged goods, raw materials, and ingredients with ease. Packaging units use them for product flow between filling, sealing, labeling, and inspection stations. FMCG companies rely on modular conveyors for lightweight product transfer, sorting, and assembly operations. They are also suitable for pharmaceutical production, cosmetics packaging, consumer goods, electronics assembly, and warehouse automation. Their ability to handle curves, inclines, bottle transfers, and multi-directional movement makes modular conveyors a preferred choice in spaces where layout customization is required.

Safety Features

Packveyor ensures that every modular conveyor is designed with operator and product safety in mind. The smooth plastic belt structure reduces the risk of pinch points and supports safe movement of both workers and products. Side guides prevent items from slipping during transfer, while the belt’s gripped surface supports stable movement even at inclined angles. Motors are equipped with overload and thermal protection to avoid overheating during long shifts. Enclosed drive components reduce accidental contact, and the rounded belt links avoid sharp edges. The easy-to-clean belt surface also helps maintain hygiene in industries that follow strict safety and quality standards.

Installation & Setup Process

The installation of a modular conveyor is carried out with precise engineering to ensure efficient operation. The process begins with preparing and leveling the support structure, followed by assembling the modular belt segments based on the required length and configuration. Wear strips and guiding rails are installed to ensure smooth belt glide. The drive and tail-end sprockets are mounted accurately to prevent belt misalignment. After connecting the motor and drive assembly, belt tensioning and tracking adjustments are performed. Once assembled, the conveyor undergoes a full test run with sample loads to ensure proper speed, noise control, and stable flow. The modular design makes future layout changes or extensions quick and hassle-free.

Benefits of Choosing Packveyor Modular Conveyors

Packveyor Modular Conveyors offer unmatched flexibility and ease of customization, making them ideal for facilities with evolving workflow needs. Their plastic modular belts support curves, elevations, and varying layouts without the need for complex mechanical structures. The system offers low noise, low maintenance, and easy cleaning—especially valuable in food, pharma, and hygiene-sensitive environments. With excellent durability, corrosion resistance, and fast belt replacement, downtime is significantly reduced. The conveyors integrate effortlessly with fillers, packers, inspection units, labeling machines, and robotic systems. Overall, they enhance productivity, reduce manual handling, and support a smooth, safe, and scalable material flow.

Why Choose Packveyor Modular Conveyors

Highly customizable layouts

Easy to clean and maintain

Hygienic, durable modular belt system

Suitable for curves, inclines & multi-directional flow

Smooth operation with minimal power consumption

Long life components with fast replacement design

Perfect for automation and high-speed lines

Built for industries with strict quality standards