Contact with

us for any

soluton

Call Anytime

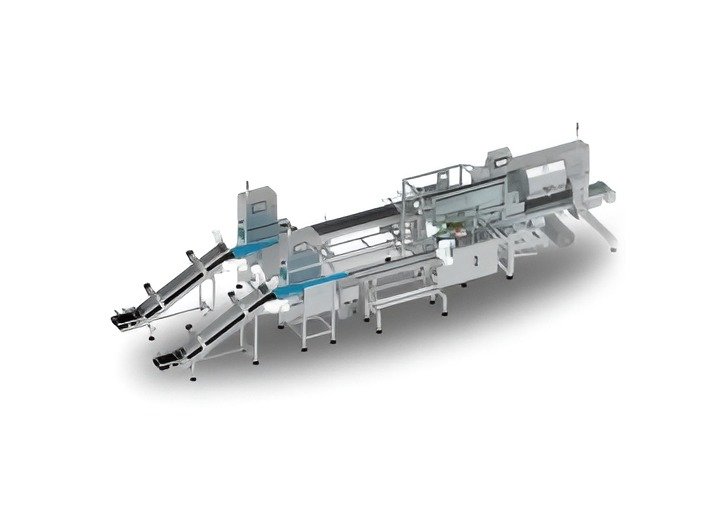

Secondary Packaging

Efficient, Safe & Streamlined Product Protection for Industrial Distribution

Secondary Packaging is a crucial stage in the packaging workflow where primary-packed products are grouped, protected, and prepared for safe storage, handling, and transportation. This level of packaging ensures that items remain secure during long-distance movement, warehousing, and bulk distribution—reducing damage, improving traceability, and supporting efficient supply chain operations.

Packveyor’s Secondary Packaging solutions are designed to enhance productivity, ensure uniform packaging quality, and integrate seamlessly with automated lines, conveyors, and end-of-line equipment.

Key Features :

Build Quality

Strong structural frames for stable operation

Durable components designed for 24×7 industrial use

Precision conveyor integration for smooth product transfer

High-quality rollers, belts, and guides optimized for packaging lines

Rust-resistant and dust-resistant construction

Clear, ergonomic design for operator accessibility

Industrial Applications

FMCG & food processing units

Pharmaceutical manufacturing

Consumer goods & cosmetics

E-commerce fulfillment centers

Electronics & appliance packaging

Beverage & dairy product handling

Automotive components

Warehouse order consolidation and dispatch

Safety Features

Emergency stop switches for operator protection

Anti-slip conveying surfaces for stable product movement

Safety guards on sealing and folding mechanisms

Overload protection motors and drives

Smooth-edge designs to avoid accidental injuries

Controlled roller/belt movement for delicate products

Installation & Setup Process

Positioning and leveling of packaging modules

Integration with infeed/outfeed conveyors

Setup of guides, stops, and alignment rails

Motor, sensor, and control panel installation

Folding, sealing, strapping, or taping unit alignment

System synchronization with upstream machines

Final run test with real products for accuracy

Benefits of Choosing Packveyor Secondary Packaging Solutions

Supports faster and more uniform packaging

Reduces manual labor and minimizes errors

Ensures better product protection during transportation

Compatible with boxes, cartons, shrink packs, and bundles

Smooth integration with conveyors and automation lines

Long-lasting construction with low maintenance

Full customization based on production requirements

Improves operational efficiency and dispatch accuracy

Why Choose Packveyor for Secondary Packaging

Expertise in designing packaging-friendly conveyor integrations

High reliability even at high-speed production settings

Hygienic and durable materials suitable for food & pharma

Flexible configurations for different product sizes

Proven performance in diverse industrial sectors

Engineered to support automation and future expansion